Posted by Admin on 08-07-2023 in Shiksha hub

Stone Cutter (Cutting Machine Operator) Introduction, Admission, Registration, Eligibility, Duration, Fees, Syllabus 2024

Introduction about Stone Cutter (Cutting Machine Operator)?

What is Stone Cutting?

Stone cutting is a meticulous craft that has been crucial in the construction and design industries for centuries. It involves the precise shaping and sizing of natural and engineered stones, making them suitable for various applications. From majestic marble sculptures to functional granite countertops, stone cutters are the skilled artisans behind these creations.

The Role of a Stone Cutter

A stone cutter, often referred to as a cutting machine operator, is a professional responsible for operating and maintaining cutting machines that transform rough stone blocks into exquisite finished products. These skilled individuals play a pivotal role in the stone processing industry.

Importance of Stone Cutters in the Industry

The work of a stone cutter is indispensable in architecture, interior design, and landscaping. Their craftsmanship ensures that stones are not only aesthetically pleasing but also functional and durable. Stone cutters are the bridge between raw materials and stunning final installations.

Qualifications and Skills

Educational Requirements

To become a stone cutter, one typically needs a high school diploma or equivalent. While formal education beyond this level is not mandatory, it can be advantageous for career growth. Many aspiring stone cutters opt for vocational or technical training to gain a competitive edge.

Necessary Skills

Stone cutting demands precision and attention to detail. As a stone cutter, you need to possess exceptional hand-eye coordination, spatial awareness, and a knack for problem-solving. Additionally, familiarity with the latest cutting technologies is essential.

Safety Measures

Working with heavy machinery and sharp tools requires a strong commitment to safety. Stone cutters must adhere to safety guidelines, wear protective gear, and be trained in first aid procedures to prevent accidents.

Types of Cutting Machines

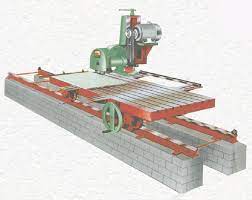

Bridge Saws

Bridge saws are one of the most common cutting machines used in the industry. They are stationary, large-scale machines equipped with diamond-tipped blades. These machines make precise cuts on stone slabs, ensuring accuracy in the final product.

Wire Saws

Wire saws are versatile tools that use a continuous loop of diamond-coated wire. They are ideal for cutting irregular shapes and large blocks of stone, making them essential for sculptors and architectural projects.

Water Jets

Water jet cutting machines use high-pressure water mixed with abrasive materials to cut through stone. This method is known for its precision and versatility, making it suitable for delicate and intricate designs.

Work Environment

Indoor vs. Outdoor Work

Stone cutters may work indoors in manufacturing facilities or outdoors on construction sites. The choice of work environment depends on the specific job and project requirements.

Safety Precautions

Safety is paramount in the stone cutting industry. Stone cutters must be aware of the potential risks associated with the job, such as flying debris and equipment-related accidents. Adhering to safety protocols is non-negotiable.

Daily Responsibilities

Material Inspection

Before the cutting process begins, stone cutters carefully inspect the stone material for flaws, cracks, or imperfections. Identifying these issues early ensures the final product's quality.

Operating the Cutting Machine

Operating cutting machines, stone cutters make precise cuts according to project specifications. They must constantly monitor the machinery to ensure accurate results.

Maintaining Equipment

Routine maintenance of cutting machines is essential to prevent breakdowns and ensure safety. Stone cutters are responsible for cleaning, sharpening, and repairing equipment as needed.

Challenges Faced by Stone Cutters

Challenges Faced by Stone Cutters

Health Risks

Stone cutters may face health risks due to prolonged exposure to dust and noise. They must take precautions to protect their well-being.

Technological Advancement

Keeping up with technological advancements in the industry is crucial. Stone cutters need to adapt to new tools and methods to stay competitive in the market.

Importance in the Construction Industry

Importance in the Construction Industry

Stone in Construction

The use of stone in construction has a rich history. Stone cutters contribute to the construction industry by providing high-quality materials that enhance the aesthetic and structural aspects of buildings.

Stone Cutter's Impact

The precision and expertise of stone cutters play a significant role in the success of construction projects. Their work can elevate the overall quality and value of a structure.

How can I apply for admission to Stone Cutter (Cutting Machine Operator) program?

Training and Certification

Apprenticeships

To kickstart a career as a stone cutter (cutting machine operator), one common path is through apprenticeships. These programs allow individuals to learn the trade by working alongside experienced professionals. Here's how you can apply for an apprenticeship in this field:

Research Local Opportunities: Begin by researching local stonemasonry or construction companies that offer apprenticeships. You can find these through online job boards, trade organizations, or by contacting companies directly.

Prepare a Resume: Create a professional resume that highlights your education, relevant skills, and any previous work experience. Even if it's not directly related to stone cutting, showcasing your commitment and work ethic can be beneficial.

Submit Applications: Check for apprenticeship openings and submit your application to the companies you're interested in. Make sure to follow their specific application process, which may include online forms or sending your resume via email.

Interview and Assessment: If your application is successful, you may be invited for an interview or an assessment. Be prepared to discuss your interest in stone cutting and why you're a suitable candidate.

Get Hired: Once you pass the interview and assessment, you'll likely be hired as an apprentice. During your apprenticeship, you'll work under the guidance of experienced stone cutters, learning the trade hands-on.

Certification Programs

While apprenticeships are a valuable route, some individuals may prefer a more structured learning environment. Certification programs are another option to gain the necessary skills and knowledge. Here's how to apply for admission to a stone cutting certification program:

Find Accredited Programs: Search for accredited stone cutting certification programs at technical schools, community colleges, or vocational training centers. Make sure the program is recognized by industry standards.

Review Admission Requirements: Each program may have specific admission requirements, which can include a high school diploma or GED, proof of age, and possibly a background check. Review these requirements to ensure you meet them.

Complete the Application: Submit the application for the program you wish to join. This typically involves filling out an online application form, providing necessary documentation, and paying any application fees.

Financial Aid and Scholarships: Explore potential financial aid options or scholarships that can help cover the cost of tuition and materials. Many vocational schools offer assistance to eligible students.

Interview or Assessment: Some programs may require an interview or skills assessment to gauge your suitability for the program. Be prepared to discuss your interest in stone cutting and demonstrate any relevant skills.

Enroll and Attend: If you're accepted, enroll in the certification program and attend classes as scheduled. These programs provide structured education, practical training, and hands-on experience.

Remember that the specific application process can vary depending on the educational institution or company offering the program. It's essential to research and follow their guidelines for the best chance of admission. Stone cutting is a skilled trade that can be highly rewarding, and obtaining the right education and experience is the first step towards a successful career as a stone cutter.

What is the eligibility for Stone Cutter (Cutting Machine Operator)?

Training and Certification

Apprenticeships

To kickstart a career as a stone cutter (cutting machine operator), one common path is through apprenticeships. These programs allow individuals to learn the trade by working alongside experienced professionals. Here's how you can apply for an apprenticeship in this field:

Research Local Opportunities: Begin by researching local stonemasonry or construction companies that offer apprenticeships. You can find these through online job boards, trade organizations, or by contacting companies directly.

Prepare a Resume: Create a professional resume that highlights your education, relevant skills, and any previous work experience. Even if it's not directly related to stone cutting, showcasing your commitment and work ethic can be beneficial.

Submit Applications: Check for apprenticeship openings and submit your application to the companies you're interested in. Make sure to follow their specific application process, which may include online forms or sending your resume via email.

Interview and Assessment: If your application is successful, you may be invited for an interview or an assessment. Be prepared to discuss your interest in stone cutting and why you're a suitable candidate.

Get Hired: Once you pass the interview and assessment, you'll likely be hired as an apprentice. During your apprenticeship, you'll work under the guidance of experienced stone cutters, learning the trade hands-on.

Certification Programs

While apprenticeships are a valuable route, some individuals may prefer a more structured learning environment. Certification programs are another option to gain the necessary skills and knowledge. Here's how to apply for admission to a stone cutting certification program:

Find Accredited Programs: Search for accredited stone cutting certification programs at technical schools, community colleges, or vocational training centers. Make sure the program is recognized by industry standards.

Review Admission Requirements: Each program may have specific admission requirements, which can include a high school diploma or GED, proof of age, and possibly a background check. Review these requirements to ensure you meet them.

Complete the Application: Submit the application for the program you wish to join. This typically involves filling out an online application form, providing necessary documentation, and paying any application fees.

Financial Aid and Scholarships: Explore potential financial aid options or scholarships that can help cover the cost of tuition and materials. Many vocational schools offer assistance to eligible students.

Interview or Assessment: Some programs may require an interview or skills assessment to gauge your suitability for the program. Be prepared to discuss your interest in stone cutting and demonstrate any relevant skills.

Enroll and Attend: If you're accepted, enroll in the certification program and attend classes as scheduled. These programs provide structured education, practical training, and hands-on experience.

Remember that the specific eligibility requirements can vary depending on the educational institution or company offering the program. It's essential to research and follow their guidelines for the best chance of admission. Stone cutting is a skilled trade that can be highly rewarding, and obtaining the right education and experience is the first step towards a successful career as a stone cutter.

How long does it takes to complete a Stone Cutter (Cutting Machine Operator) program?

The duration of a stone cutter (cutting machine operator) program can vary depending on the type of training or education you choose:

Apprenticeships: Apprenticeships typically last around 3 to 4 years. During this time, you'll work under the guidance of experienced stone cutters to gain practical skills and knowledge. The duration may vary depending on the complexity of the work and the specific requirements of the apprenticeship program.

Certification Programs: Stone cutting certification programs offered by vocational schools, community colleges, or technical training centers often take around 1 to 2 years to complete. These programs provide a structured curriculum that includes both classroom instruction and hands-on training.

The length of the program can also be influenced by factors such as the specific skills and techniques being taught and the institution's scheduling. It's essential to check with the program or school you are interested in to get accurate information on the duration of their stone cutter program.

What are potential career opportunities after Stone Cutter (Cutting Machine Operator)?

Career Opportunities

Growth Potential

Aspiring stone cutters have the potential to advance in their careers by specializing in specific types of stone or techniques. Some may choose to become master stone cutters or open their own businesses. Here are some potential career opportunities in the field:

Master Stone Cutter: With years of experience, a stone cutter can become a master of the trade. They often work on high-profile projects, creating intricate designs and overseeing other stone cutters.

Specialized Stone Cutter: Stone cutters can specialize in working with specific types of stone, such as granite, marble, limestone, or quartz. Specialization can lead to expertise in handling certain materials and designs.

Artisan or Sculptor: Some stone cutters transition into careers as artisans or sculptors, creating unique stone artworks, statues, and sculptures.

Quality Control Specialist: Stone cutters with a keen eye for detail can work as quality control specialists, ensuring the precision and quality of the final products.

Instructor or Trainer: Experienced stone cutters can become instructors or trainers, passing their knowledge and skills on to the next generation of professionals in the field.

Business Owner: Entrepreneurial stone cutters may choose to start their own stone cutting businesses. This path allows them to take on various projects and potentially expand their operations.

Specializations

Stone cutters can specialize in various areas, including:

Architectural Stone Cutting: Focusing on creating stone components for buildings, including facades, pillars, and decorative elements.

Monumental Stonework: Crafting gravestones, memorials, and monuments for cemeteries.

Countertop Fabrication: Working with homeowners and designers to create custom countertops for kitchens and bathrooms.

Artistic Sculpture: Creating intricate stone sculptures and artworks for public installations or galleries.

Restoration and Conservation: Specializing in the restoration and conservation of historical stone structures and sculptures.

Landscape Stonework: Designing and creating stone features for outdoor landscapes, such as retaining walls and pathways.

The career opportunities for stone cutters are diverse, allowing individuals to explore various paths within the stone cutting and masonry industry. The choice of specialization often depends on personal interests, skills, and market demand.

Syllabus of Stone Cutter (Cutting Machine Operator)

Semester 1: Introduction to Stone Cutting

Course Introduction

Safety Procedures

Stone Types and Characteristics

Basic Hand Tools and Equipment

Stone Cutting Fundamentals

Measurement and Layout

Semester 2: Stone Cutting Techniques

Advanced Hand Tools and Equipment

Basic Cuts and Shaping

Precision Measurement

Introduction to Cutting Machines

Maintenance and Care of Tools

Semester 3: Advanced Cutting Techniques

Types of Cutting Machines

Bridge Saws and Wire Saws

Water Jet Cutting

Computer-Aided Design (CAD) in Stone Cutting

Complex Cuts and Inlays

Quality Control and Inspection

Semester 4: Specializations

Choosing a Specialization (e.g., architectural stonework, sculpting, countertop fabrication)

Specialized Tools and Equipment

Specialization-Specific Techniques

Customization and Creativity in Stone Cutting

Semester 5: Safety and Environmental Practices

Workplace Safety Regulations

Handling Hazardous Materials

Environmental Impact of Stone Cutting

Sustainable Stone Cutting Practices

Health and Safety Procedures

Semester 6: Work Experience

On-the-Job Training or Apprenticeship

Real-World Stone Cutting Projects

Practical Application of Skills

Supervised Work Experience

Safety and Best Practices in the Field

Semester 7: Business Skills (Optional)

Business Fundamentals for Stone Cutters

Budgeting and Cost Estimation

Marketing and Client Relations

Business Management

Starting and Managing a Stone Cutting Business

Semester 8: Advanced Topics

Emerging Technologies in Stone Cutting

Historic Restoration and Conservation

Artistry in Stone Cutting

Advanced Computer-Aided Design (CAD)

Project Management

Internship opportunities after completing Stone Cutter (Cutting Machine Operator)?

After completing a stone cutter (cutting machine operator) program, individuals often seek internship opportunities to gain practical experience and further refine their skills. Internships are valuable as they provide real-world exposure to the profession, the chance to work with experienced professionals, and opportunities to build a network in the stone cutting industry. Here are some internship opportunities you can explore:

Apprenticeship Continuation: If you began your career with an apprenticeship, continuing to work with the same company is an excellent choice. You can gain more hands-on experience, refine your skills, and work on a wider range of projects.

Stone Fabrication Companies: Many stone fabrication companies offer internships. Here, you can learn the intricacies of stone cutting machinery, different types of stone, and fabrication techniques. These internships often lead to full-time employment.

Masonry and Construction Firms: Interning with masonry or construction firms that use stone products is another option. This experience allows you to see how stone products are integrated into construction projects.

Artisan Studios: If you have an interest in stone sculpture or artistic work, consider interning at an artisan studio. You can learn the art of sculpting and work on creating unique stone sculptures.

Stone Restoration Companies: These companies specialize in restoring and conserving historic stone structures and sculptures. Interning with them can teach you valuable skills related to restoration and preservation.

Countertop Fabricators: If you're interested in countertop fabrication, intern with companies that specialize in creating custom stone countertops. This experience will familiarize you with countertop-specific techniques and materials.

Landscape Stonework Companies: For those interested in landscaping and outdoor stone features, interning with landscape stonework companies is a great choice. You can learn about designing and building stone structures for outdoor spaces.

Architectural Stone Companies: These companies focus on creating architectural elements like facades, columns, and ornate stonework for buildings. Interning with them will provide insights into the world of architectural stone cutting.

To find internship opportunities, consider the following steps:

Check with Your School: Many stone cutter programs have connections with local businesses and can help you find internship opportunities.

Job Boards and Websites: Look for internship listings on job boards, company websites, or industry-specific websites related to stone cutting and masonry.

Networking: Attend industry events, conferences, and trade shows to network with professionals. They may know of internship opportunities or be willing to mentor you.

Contact Companies Directly: Reach out to stone fabrication, construction, or other related companies in your area. Inquire about internship possibilities, even if they don't have postings.

Career Services: Utilize your school's career services department for assistance in finding internship opportunities.

Internships are a critical step in building your career as a stone cutter, as they allow you to gain practical experience, enhance your skills, and make valuable connections within the industry.

Scholarship and grants for Stone Cutter (Cutting Machine Operator)?

Scholarships and grants can provide financial assistance to individuals pursuing a career as a stone cutter (cutting machine operator). While these opportunities may not be as numerous as in some other fields, there are still options to explore. Here are some potential sources of financial aid:

Trade and Vocational Schools: Many trade and vocational schools that offer stone cutter programs have their own scholarship programs. Check with the school you plan to attend to see if they offer scholarships or grants to students pursuing a career in stone cutting.

Industry Associations: Some industry associations related to masonry and stone cutting may offer scholarships. For example, organizations like the Mason Contractors Association of America (MCAA) or the National Stone, Sand & Gravel Association (NSSGA) may have scholarship opportunities for students in the field.

Local Trade Unions: If you plan to join a trade union as a stone cutter, inquire about any scholarship or grant programs they may have for apprentices or members.

Community and Technical Colleges: Many community and technical colleges offer scholarships to students pursuing vocational programs, including stone cutting. Check with the financial aid office of the college you plan to attend.

State and Federal Grants: Some state and federal programs provide financial assistance to students pursuing vocational and technical education. Filling out the Free Application for Federal Student Aid (FAFSA) can help you determine your eligibility for government grants.

Private Organizations and Foundations: Some private organizations and foundations may offer scholarships or grants for students in vocational or trade programs. These opportunities can vary widely, so it's worth researching organizations that align with your career goals.

Employer Sponsorship: If you're already working in the field or plan to work for a specific stone cutting company, inquire whether your employer offers any tuition reimbursement or sponsorship programs for further education in the field.

Online Scholarship Search Engines: Utilize scholarship search engines like Fastweb, Scholarships.com, and Cappex to find scholarships that may be relevant to your field of study. While stone cutting scholarships may be limited, you may find other opportunities that can help offset your education costs.

When applying for scholarships and grants, be sure to pay attention to eligibility requirements, application deadlines, and submission instructions. It's also a good idea to write a compelling personal statement that highlights your passion for the field and why you deserve the financial support.

FAQ,s

FAQ 1: What is a stone cutter (cutting machine operator)?

A stone cutter, or cutting machine operator, is a skilled professional responsible for operating machinery to shape and cut natural and engineered stone materials. They create a wide range of stone products used in construction, architecture, and art.

FAQ 2: What qualifications are required to become a stone cutter?

To become a stone cutter, you typically need a high school diploma or equivalent. Many stone cutters also pursue vocational or technical training in the field to gain specialized skills. Additionally, apprenticeships and certification programs can enhance your qualifications.

FAQ 3: What types of cutting machines do stone cutters use?

Stone cutters use various cutting machines, including bridge saws, wire saws, and water jets. Each type of machine is suited for specific cutting tasks and materials.

FAQ 4: Is stone cutting a safe profession?

Safety is a top priority in stone cutting. Stone cutters must follow strict safety protocols and wear protective gear to prevent accidents. Proper training and adherence to safety guidelines help ensure a safe working environment.

FAQ 5: What career opportunities are available for stone cutters?

Stone cutters can pursue various career paths, including becoming master stone cutters, specializing in specific types of stone, or starting their own businesses. They may also work in areas such as architectural stone cutting, sculpture, or historic restoration.

FAQ 6: What is the demand for stone cutters in the job market?

The demand for stone cutters can vary depending on the region and the specific industry. Generally, there is a consistent need for skilled stone cutters in construction, design, and art-related fields.

FAQ 7: Are there risks associated with the profession of stone cutting?

Yes, stone cutters may face certain risks, including exposure to dust and noise, as well as the potential for accidents while operating heavy machinery. It's essential for stone cutters to adhere to safety measures to mitigate these risks.

FAQ 8: How has technology influenced the field of stone cutting?

Technology has significantly impacted stone cutting, with the introduction of computer-aided design (CAD) systems, advanced cutting machinery, and precision tools. These technological advancements have improved the efficiency and precision of stone cutting.

FAQ 9: Can I specialize in a particular type of stone as a stone cutter?

Yes, stone cutters can specialize in working with specific types of stone, such as granite, marble, limestone, or quartz. Specialization allows you to become an expert in handling particular materials and meeting unique design requirements.

FAQ 10: How can I find internship opportunities as a stone cutter?

To find internship opportunities, you can check with your school's career services, explore job boards, contact stone fabrication companies, attend industry events, and network with professionals in the field. Internships provide valuable hands-on experience.