Posted by Admin on 29-08-2023 in Shiksha hub

Metal Active Gas/ Gas Metal Arc Welder (MIG/MAG/GMAW): IQP, Introduction, Admission, Registration, Eligibility, Duration, Fees, Syllabus 2024

Introduction about METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

MIG/MAG/GMAW welding is a fusion welding process that employs a continuously fed consumable wire electrode and an inert or active gas shield to protect the weld pool from atmospheric contamination. The term "inert" refers to gases like argon or helium, while "active" gases may include a blend of carbon dioxide and argon.

Historical Evolution of MIG/MAG/GMAW Welding

The roots of MIG/MAG/GMAW welding trace back to the early 19th century, with significant advancements occurring in the mid-20th century. Notable innovators, such as P.O. Nobel and H.M. Hobart, played pivotal roles in refining the process.

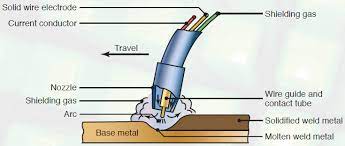

Components of a MIG/MAG/GMAW Welding Setup

Power Source

The power source supplies the electrical energy required to create an arc between the electrode wire and the workpiece. It regulates parameters like voltage and amperage.

Wire Feeder

The wire feeder propels the consumable electrode wire through the welding gun at a controlled rate.

Shielding Gas Supply

A cylinder containing the selected shielding gas is connected to the welding system, ensuring a consistent flow to protect the welding area.

Welding Gun

The welding gun is the apparatus through which the consumable wire electrode and shielding gas are dispensed, and the arc is initiated.

How can I apply for admission to METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

To apply for admission to the METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program, follow these steps:

Visit the Official Website: Start by visiting the official website of the institution or organization offering the MIG/MAG/GMAW program.

Navigate to the Admission Section: Look for the 'Admissions' or 'Apply Now' section on the website. This is where you'll find information about the application process.

Review Admission Requirements: Familiarize yourself with the admission requirements for the MIG/MAG/GMAW program. This may include educational qualifications, prerequisites, and any specific documentation needed.

Create an Account: Many institutions require applicants to create an online account. Provide the necessary information to set up your profile.

Complete the Application Form: Fill out the application form with accurate and up-to-date information. Be sure to double-check for any errors before submitting.

Submit Required Documents: Upload or submit any required documents, such as transcripts, certificates, identification, and proof of any relevant work experience.

Pay Application Fee: Some institutions may require an application fee. Make sure to complete this step if applicable.

Personal Statement or Essay (if required): Write a personal statement or essay as specified in the application instructions. This is an opportunity to showcase your interest in MIG/MAG/GMAW and your suitability for the program.

Letters of Recommendation (if required): Arrange for any required letters of recommendation to be sent directly to the institution.

Submit the Application: Review all the information you've provided, then submit your application.

Track Application Status: Keep an eye on your application status. You may be able to do this through the online portal or by contacting the admissions office.

Prepare for Interviews or Tests (if required): Some programs may require interviews, assessments, or tests as part of the admission process. Be sure to prepare accordingly.

Receive Admission Decision: Once the admissions committee has reviewed your application, you will receive an admission decision. This may take some time, so be patient.

Acceptance and Enrollment: If you are accepted, follow the instructions provided to confirm your acceptance and complete the enrollment process.

Financial Considerations: Review any financial aid or scholarship opportunities available for the program.

What is the eligibility for METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

To be eligible for the METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program, candidates typically need to meet the following criteria:

Educational Qualifications:

A high school diploma or equivalent is usually required. Some programs may have specific coursework prerequisites in subjects like mathematics and physics.

Age Requirements:

Candidates are typically required to be at least 18 years old at the time of enrollment. Some programs may have specific age restrictions.

Physical Fitness:

Due to the nature of welding, applicants may need to meet certain physical fitness standards. This can include good hand-eye coordination, manual dexterity, and the ability to lift and carry heavy objects.

Safety Training and Certifications:

Some programs may require applicants to have completed basic safety training or hold certain certifications, such as OSHA (Occupational Safety and Health Administration) certifications.

English Language Proficiency:

Since the program is conducted in English, applicants may need to demonstrate proficiency in the language. This can be through standardized tests like TOEFL or other equivalent measures.

Previous Welding Experience (if applicable):

While not always required, having some prior experience or knowledge in welding can be beneficial. Programs may offer different tracks for beginners and experienced welders.

Passing Entrance Examinations (if applicable):

Some institutions may require applicants to pass specific entrance examinations related to welding concepts and skills.

Interview or Assessment (if applicable):

Depending on the program, applicants may be required to undergo an interview or practical assessment to demonstrate their interest and aptitude for welding.

Submission of Required Documentation:

This may include transcripts, certificates, identification, and any other documents specified by the institution.

How long does it takes to complete a METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

The duration to complete a METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program can vary depending on several factors, including the specific curriculum and the institution offering the course. Generally, these programs are designed to provide comprehensive training in welding techniques. Here are some common duration scenarios:

Full-Time Programs:

A full-time MIG/MAG/GMAW program can typically be completed in approximately 6 to 12 weeks. This format often involves intensive daily instruction and hands-on practice.

Part-Time or Evening Programs:

Part-time or evening programs are designed to accommodate individuals who may have other commitments. These programs may span over a period of 3 to 6 months, with classes held in the evenings or on weekends.

Apprenticeships:

Some institutions offer apprenticeship programs where students learn while working under the guidance of experienced welders. These programs can take several years to complete, as they combine on-the-job training with classroom instruction.

Online or Hybrid Programs:

Online or hybrid programs may allow for a more flexible schedule. These can range from a few months to a year or more, depending on the structure of the program.

Advanced Certifications or Specializations:

For individuals seeking advanced certifications or specializations within MIG/MAG/GMAW, additional training may be required. These can vary in duration, typically ranging from a few weeks to several months.

What are potential career opportunities after METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

Completing a METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program can open up various career opportunities in the welding and metalworking industry. Here are some potential career paths:

Welder:

As a certified MIG/MAG/GMAW welder, you can work in various industries such as manufacturing, construction, automotive, aerospace, and shipbuilding. You'll be responsible for creating strong, durable welds on metal components.

Welding Technician:

Technicians provide support to professional welders by setting up welding equipment, preparing materials, and ensuring a safe work environment. They may also assist in quality control and inspection processes.

Welding Inspector:

Inspectors are responsible for examining welds to ensure they meet industry standards and specifications. They play a crucial role in quality assurance and may work in construction, manufacturing, or fabrication settings.

Metal Fabricator:

Fabricators work with metal to create structures, components, and products. They read blueprints, use various cutting and shaping tools, and assemble parts through welding or other joining techniques.

Pipefitter:

Pipefitters specialize in the installation, maintenance, and repair of pipes, tubes, and related components. They work in industries such as plumbing, heating, ventilation, and air conditioning.

Boilermaker:

Boilermakers construct, install, and repair large containers, such as boilers, vats, and tanks, that hold liquids and gases. They often work in industries like power generation and manufacturing.

Sheet Metal Worker:

Sheet metal workers fabricate and install products made from thin metal sheets. This can include ductwork for HVAC systems, roofing, and siding for buildings.

Metalworking Machine Operator:

Operators work with specialized machines to cut, shape, and form metal materials. They may operate CNC machines or other automated equipment.

Welding Instructor:

With additional experience and potentially further education, you may choose to become an instructor, teaching aspiring welders the skills and techniques needed in the field.

Welding Engineer:

Welding engineers design, develop, and oversee welding processes and procedures to ensure structural integrity and quality in various applications. They may work in research and development or manufacturing settings.

Robotics Welding Technician:

With the integration of automation in welding, technicians skilled in operating and maintaining robotic welding systems are in demand.

Supervisor or Managerial Roles:

With experience, you may advance to supervisory or managerial positions, overseeing welding teams, projects, and operations.

Syllabus of METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

While specific syllabi can vary between institutions, a typical METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program is structured semester-wise to provide a comprehensive understanding of welding techniques. Below is a sample syllabus:

Semester 1: Introduction to Welding Fundamentals

Course Title: Introduction to Welding Technology

Overview of Welding Processes

Safety Procedures in Welding

Welding Equipment and Tools

Course Title: Blueprint Reading and Welding Symbols

Interpretation of Welding Blueprints

Understanding Welding Symbols and Notations

Course Title: Welding Metallurgy and Materials

Properties of Metals and Alloys

Heat Treatment and Weldability

Course Title: Introduction to MIG/MAG/GMAW Welding

Principles of MIG/MAG/GMAW

Set-Up and Operation of Welding Equipment

Semester 2: Practical Application and Techniques

Course Title: Hands-On Welding Practice (MIG/MAG/GMAW)

Practice on Various Joint Configurations

Welding in Different Positions

Course Title: Welding Inspection and Quality Control

Non-Destructive Testing (NDT)

Visual Inspection and Defect Recognition

Course Title: Advanced MIG/MAG/GMAW Techniques

Pulse Welding

Spray Arc Welding

Semester 3: Specializations and Advanced Topics

Course Title: Welding for Specific Industries

Automotive Welding

Aerospace Welding

Shipbuilding and Maritime Welding

Course Title: Welding Automation and Robotics

Introduction to Welding Robots

Programming and Operation

Course Title: Welding Codes and Standards

AWS (American Welding Society) Codes

ASME (American Society of Mechanical Engineers) Codes

Semester 4: Capstone Project and Certification

Course Title: Capstone Project in MIG/MAG/GMAW

Design and Execute a Welding Project

Documentation and Presentation

Course Title: Welding Certification and Industry Readiness

Preparation for Welding Certifications

Resume Building and Job Search Strategies

Internship opportunities after completing METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

After completing a METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program, graduates have various internship opportunities available to further enhance their skills and gain valuable industry experience. Here are some potential internship opportunities:

Welding Technician Intern:

Work alongside experienced welding technicians to set up welding equipment, prepare materials, and assist in welding operations.

Welding Inspector Intern:

Interns may assist in inspecting welds for quality and compliance with industry standards, under the guidance of certified welding inspectors.

Metal Fabrication Intern:

Gain hands-on experience in metal fabrication shops, assisting in the creation of structures and components from metal materials.

Manufacturing Intern:

Interns may work in manufacturing facilities, assisting in various aspects of the production process, including welding operations.

Construction Welding Intern:

Interns may have the opportunity to work on construction sites, assisting in welding tasks related to building and infrastructure projects.

Aerospace Welding Intern:

Gain experience in aerospace manufacturing facilities, working on projects related to aircraft and aerospace components.

Automotive Welding Intern:

Interns may work in automotive repair shops or manufacturing plants, assisting in welding operations related to vehicle maintenance or production.

Shipbuilding and Maritime Welding Intern:

Work in shipyards or maritime facilities, gaining experience in welding for the construction and repair of ships and maritime structures.

Pipeline Welding Intern:

Interns may work on pipeline construction projects, gaining experience in welding for the oil and gas industry.

Robotics Welding Technician Intern:

Gain experience in facilities that utilize robotic welding systems, assisting in the operation and maintenance of welding robots.

Research and Development Intern:

Work in R&D departments of welding equipment manufacturers or related industries, assisting in the development of new welding technologies and processes.

Environmental and Safety Intern:

Interns may work with environmental and safety teams in welding facilities, focusing on safety protocols, environmental compliance, and occupational health.

Scholarships and grants for METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP

There are various scholarships and grants available for individuals pursuing a METAL INERT GAS/METAL ACTIVE GAS/GAS METAL ARC WELDER (MIG/MAG/GMAW): IQP program. These financial aids can help offset the costs of tuition, books, and other educational expenses. Here are some potential sources of scholarships and grants:

Institutional Scholarships:

Many educational institutions offering welding programs have their own scholarships for students enrolled in MIG/MAG/GMAW courses. These may be based on academic merit, financial need, or specific criteria related to the program.

Industry Associations and Organizations:

Welding-related associations and organizations, such as the American Welding Society (AWS), offer scholarships for students pursuing welding education. These scholarships are often targeted towards individuals who plan to enter the welding profession.

Foundation Scholarships:

Various foundations and trusts provide scholarships for students in technical and vocational programs, including welding. These organizations may have specific criteria or preferences for applicants.

Government Grants and Scholarships:

Government agencies at the federal, state, and local levels may offer grants and scholarships for students pursuing vocational and technical education. This can include programs related to welding.

Private Companies and Industry Partners:

Some private companies and industry partners in the welding and metalworking sector offer scholarships to support students in gaining welding skills. These scholarships may be tied to future employment with the company.

Community and Civic Organizations:

Local community groups, service organizations, and civic clubs may have scholarship programs available for students in technical fields, including welding.

Nonprofit Organizations:

Nonprofit organizations with a focus on education and workforce development may offer scholarships for individuals pursuing vocational and technical training, including welding.

Military and Veterans Benefits:

Military service members and veterans may be eligible for education benefits, including scholarships and grants, through programs like the GI Bill.

Diversity and Inclusion Scholarships:

Some organizations and foundations specifically offer scholarships to support underrepresented groups in the welding industry, including women and minorities.

Online Scholarship Databases:

Websites like Fastweb, Scholarships.com, and College Board's Scholarship Search allow students to search for scholarships based on their field of study, including welding.

Conclusion

Metal Inert Gas (MIG), Metal Active Gas (MAG), and Gas Metal Arc Welding (GMAW) collectively refer to a versatile and widely used welding process. This article delves into the intricacies of these welding techniques, providing a comprehensive overview for both beginners and seasoned professionals.

FAQ,s

What is MIG/MAG/GMAW welding?

MIG/MAG/GMAW stands for Metal Inert Gas, Metal Active Gas, and Gas Metal Arc Welding, which are all variations of a welding process that uses a continuously fed consumable wire electrode and a shielding gas to protect the weld pool.

What are the key components of a MIG/MAG/GMAW welding setup?

The main components include a power source, wire feeder, shielding gas supply, and welding gun.

What metals can be welded using MIG/MAG/GMAW?

MIG/MAG/GMAW is versatile and can be used to weld various metals, including steel, stainless steel, aluminum, and alloys of copper and nickel.

What are the advantages of MIG/MAG/GMAW welding?

Advantages include high efficiency and productivity, cleaner welds, versatility in applications, and suitability for various metals.

What are the limitations of MIG/MAG/GMAW welding?

Limitations include limited suitability for outdoor use, complexity for beginners, and a tendency for distortion in thicker metals.

What safety measures should be taken when performing MIG/MAG/GMAW welding?

Safety measures include wearing appropriate personal protective equipment (PPE), ensuring proper ventilation and fume extraction, handling compressed gases safely, and setting up a safe workspace.

What are some common applications of MIG/MAG/GMAW welding?

MIG/MAG/GMAW welding is used in the automotive industry, construction and fabrication, shipbuilding, and general metal repair and maintenance.

How can I achieve high-quality MIG/MAG/GMAW welds?

Tips include selecting the correct wire and gas, setting optimal voltage and amperage, controlling travel speed and gun angle, and conducting thorough post-weld cleaning and inspection.

What are some innovations and trends in MIG/MAG/GMAW technology?

Innovations include pulsed MIG welding, synergic control systems, and integration with robotics.

How does MIG/MAG/GMAW welding contribute to environmental sustainability?

It reduces waste and emissions, is energy-efficient, and allows for the recycling of consumables.

What kind of training and certification is available for MIG/MAG/GMAW welders?

Formal education, apprenticeships, and certification programs are available. Continuous professional development is also encouraged.

What are the cost considerations and return on investment (ROI) in MIG/MAG/GMAW?

Considerations include initial equipment costs, operational expenses, and the long-term benefits of high-quality welds.

How can I troubleshoot common issues in MIG/MAG/GMAW welding?

Tips for troubleshooting include addressing spatter and porosity, incomplete fusion, excessive heat input, and irregular bead profiles.