Posted by Admin on 01-09-2023 in Shiksha hub

Knitting Machine Operator – Circular Knitting, Introduction, Admission, Registration, Eligibility, Duration, Fees, Syllabus 2024

Introduction about KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

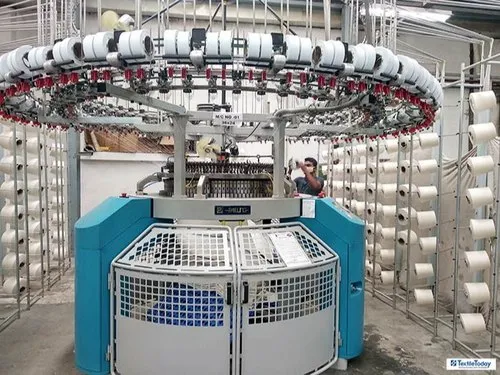

Understanding Circular Knitting

Knitting is a time-honored craft that has evolved over the centuries. Today, it's not just about hand-knitting sweaters and scarves; it's also about machine knitting, especially circular knitting. Circular knitting is a technique that involves creating seamless, tubular fabrics. This method is widely used in the textile industry for making garments like socks, hats, and seamless clothing items.

The Role of a Knitting Machine Operator

A knitting machine operator, as the name suggests, is responsible for running circular knitting machines. Their role is crucial in the textile manufacturing process. These operators work with specialized machinery that knits fabrics in a continuous loop. They need to be well-versed in the operation of circular knitting machines and ensure that the production process runs smoothly.

Skills Required for the Job

Becoming a knitting machine operator requires a specific skill set. You need to have a good understanding of the different types of circular knitting machines, as well as the ability to troubleshoot any issues that may arise during the knitting process. Patience, attention to detail, and a love for working with textiles are also essential qualities for success in this role.

Getting Started: Knitting Machine Setup

Before starting the actual knitting process, a knitting machine operator must set up the circular knitting machine. This includes loading the required yarn, ensuring the machine is in good working order, and configuring the settings for the desired fabric type and pattern. The setup phase is critical in determining the quality of the final product.

Operating the Circular Knitting Machine

Once everything is set up, the operator begins the knitting process. Circular knitting machines use a continuous loop of needles to create fabric. Operators monitor the machine's performance, making adjustments as needed, and ensure that the yarn is fed smoothly to prevent snags or breaks.

Troubleshooting Common Issues

Circular knitting machines can encounter various issues during operation, such as yarn jams, dropped stitches, or tension problems. A skilled operator should be able to identify and address these issues promptly to avoid production delays and maintain the quality of the fabric being produced.

Maintaining Quality Control

Quality control is a critical aspect of circular knitting. Operators need to regularly inspect the fabric for defects, ensure that the gauge and tension are correct, and make any necessary adjustments to maintain the desired quality standards. This attention to detail is what sets a professional knitting machine operator apart.

Safety Precautions

Working with knitting machines requires strict adherence to safety guidelines. Operators must be cautious of moving parts and sharp needles. Proper training and the use of safety equipment are essential to prevent accidents and injuries.

Career Opportunities

Becoming a skilled knitting machine operator opens doors to a range of career opportunities in the textile industry. Operators can work in garment manufacturing, textile mills, and even start their businesses if they have the entrepreneurial spirit.

The Future of Circular Knitting

As technology continues to advance, circular knitting machines are becoming more automated and efficient. The future of circular knitting holds promise for increased productivity and even more diverse fabric creations. Learning to operate these advanced machines will be a valuable skill for those entering the textile industry.

How can I apply for admission to KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

To apply for admission to become a Knitting Machine Operator specializing in Circular Knitting, you can follow these general steps:

Research Training Programs: Start by researching vocational or technical schools, community colleges, or online courses that offer training programs for knitting machine operation. Look for programs that specifically cover circular knitting.

Admission Requirements: Check the admission requirements for the chosen program. Typically, you'll need a high school diploma or equivalent. Some programs may require certain math or mechanical aptitude prerequisites.

Submit an Application: Once you've identified a suitable program, fill out the application form provided by the institution. Make sure to provide all the required personal and educational information.

Transcripts and Documents: You may need to submit your high school transcripts or equivalent certificates. Ensure your academic records are up to date and readily available.

Financial Aid: Explore financial aid options, such as scholarships, grants, or loans, if you need assistance with tuition or other related expenses.

Interview or Assessment: Some programs may require an interview or skills assessment to gauge your aptitude and interest in becoming a knitting machine operator.

Complete Required Prerequisites: If the program has specific prerequisites or requirements, ensure you meet them before the program begins.

Tuition and Fees: Understand the program's tuition and fees structure. Be prepared to pay the necessary fees or set up a payment plan.

Orientation: Attend any orientation sessions offered by the institution to familiarize yourself with the program and its expectations.

Enroll in Classes: Once admitted, register for the classes related to knitting machine operation, including those focusing on circular knitting. Pay attention to class schedules and any required textbooks or materials.

Hands-On Training: Participate actively in the hands-on training sessions. Gain experience in setting up, operating, and troubleshooting circular knitting machines.

Graduate: Successfully complete the program, fulfill any internship or practical requirements, and receive your certification or diploma as a Knitting Machine Operator.

What is the eligibility for KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

The eligibility requirements for becoming a Knitting Machine Operator specializing in Circular Knitting may vary depending on the specific training program, institution, or employer. However, here are some general eligibility criteria commonly associated with this occupation:

Educational Qualifications: In many cases, a high school diploma or its equivalent (GED) is the minimum educational requirement to become a Knitting Machine Operator. Some programs or employers may require additional math or mechanical aptitude prerequisites.

Age Requirements: There are typically no specific age requirements for pursuing this career. Knitting machine operator positions are open to individuals of various age groups.

Physical Fitness: The nature of the job may require operators to be physically fit, as they may need to stand for extended periods, handle heavy materials, and perform repetitive tasks.

Attention to Detail: A keen eye for detail is essential, as knitting machine operators need to monitor the machine's performance, detect defects in the fabric, and make necessary adjustments.

Manual Dexterity: Good hand-eye coordination and manual dexterity are important for handling the knitting machine and the yarn.

Problem-Solving Skills: Knitting machine operators should have the ability to troubleshoot common machine issues and perform minor maintenance tasks.

Patience: The job may involve repetitive tasks and the need for patience, especially when troubleshooting or adjusting the machine.

Safety Awareness: Operators must adhere to safety guidelines, use protective equipment, and be cautious of moving parts and sharp needles.

Training Program Requirements: If you're enrolling in a formal training program, you'll need to meet the admission requirements of that program. These requirements can vary from one educational institution to another.

Workplace Requirements: If you're seeking employment as a knitting machine operator, the specific qualifications required by employers may differ. They may specify additional skills or experience relevant to their particular machinery or production process.

How long does it takes to complete a KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

The duration it takes to complete a training program or course to become a Knitting Machine Operator specializing in Circular Knitting can vary depending on the specific program and the level of expertise you aim to achieve. Here are some general guidelines:

Short-Term Training Programs: Some vocational or technical schools offer short-term training programs that can be completed in a matter of weeks or a few months. These programs typically provide basic knowledge and skills to get you started in the field.

Certificate Programs: Certificate programs usually last anywhere from 6 months to a year. These programs offer a more comprehensive curriculum and hands-on training to prepare you for entry-level positions.

Associate's Degree: If you're looking for a more in-depth education, some community colleges or technical institutes offer associate's degree programs in textile-related fields. These typically take two years to complete.

On-the-Job Training: Some individuals learn to become knitting machine operators through on-the-job training. The duration of this training can vary widely and often depends on the complexity of the machinery and the specific needs of the employer.

Advanced Training: For those aiming for advanced or specialized roles in circular knitting machine operation, additional training and experience may be required, which can extend the learning period.

What are potential career opportunities after KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

Becoming a Knitting Machine Operator specializing in Circular Knitting can open up various career opportunities in the textile and manufacturing industries. Here are some potential career paths and opportunities:

Circular Knitting Machine Operator: This is the most direct career path. You can work as a circular knitting machine operator in textile mills, garment manufacturing units, or other facilities involved in fabric production. Your role will involve setting up, operating, and maintaining circular knitting machines.

Quality Control Inspector: You can pursue a career as a quality control inspector. In this role, you'll be responsible for examining fabrics produced by knitting machines to ensure they meet specific quality standards. Inspectors identify and address defects, ensuring that the finished products are of high quality.

Textile Technician: Textile technicians work in textile research and development, testing new materials, and improving existing ones. They may work in laboratories or production facilities, assisting in the development and testing of new fabrics and production methods.

Textile Production Supervisor: With experience, you can advance to a supervisory role, overseeing the work of knitting machine operators and other production staff. This position involves managing production schedules, quality control, and ensuring that the team meets production targets.

Machine Maintenance Technician: If you have strong mechanical aptitude, you can work as a machine maintenance technician, specializing in maintaining and repairing circular knitting machines. This role ensures that machinery operates efficiently and minimizes downtime.

Product Development Specialist: Product development specialists work with designers and engineers to create new textile products. They use their knowledge of circular knitting to help design innovative fabrics, clothing, and textiles for various applications.

Knitwear Designer: If you have a creative flair, you can become a knitwear designer. This career involves creating designs for knitted garments, such as sweaters, scarves, and other clothing items. Designers work with circular knitting techniques to bring their designs to life.

Entrepreneur: Some individuals choose to start their businesses in textile manufacturing. With the knowledge and skills gained as a knitting machine operator, you can establish your production unit, specializing in circular knitting for various products.

Textile Sales Representative: If you have a knack for sales and communication, you can work as a textile sales representative, selling fabrics, garments, or textiles to manufacturers, designers, and retailers.

Technical Trainer or Instructor: With experience and expertise, you can become a technical trainer or instructor, teaching others how to operate circular knitting machines and imparting your knowledge in educational or vocational settings.

Syllabus of KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

Semester 1: Fundamentals of Circular Knitting

2.1. Understanding Circular Knitting Machines

2.2. Yarn Selection and Preparation

2.3. Machine Setup and Maintenance

Semester 2: Fabric Structure and Pattern Knitting

3.1. Fabric Structures in Circular Knitting

3.2. Pattern Knitting Techniques

Semester 3: Quality Control and Troubleshooting

4.1. Quality Control in Circular Knitting

4.2. Troubleshooting Common Issues

Semester 4: Advanced Circular Knitting

5.1. Advanced Stitch Techniques

5.2. Circular Knitting for Specialized Fabrics

Semester 5: Finishing and Production

6.1. Fabric Finishing

6.2. Production Planning and Optimization

Semester 6: Internship and Practical Experience

7.1. Real-World Application

7.2. Internship and Project Completion

Career Opportunities

Semester 1: Fundamentals of Circular Knitting

2.1. Understanding Circular Knitting Machines

In the first semester, students will delve into the basics of circular knitting. This includes understanding the various types of circular knitting machines, their components, and how they function. It's crucial for a knitting machine operator to be well-versed in machine types to produce quality knitted fabrics.

2.2. Yarn Selection and Preparation

One of the fundamental skills for a circular knitting operator is knowing how to select and prepare yarn. This semester covers different yarn types, their properties, and the techniques for preparing yarn to achieve the desired fabric characteristics.

2.3. Machine Setup and Maintenance

To ensure smooth operations, students will learn how to set up circular knitting machines and perform routine maintenance. This is vital for preventing breakdowns and maximizing machine efficiency.

Semester 2: Fabric Structure and Pattern Knitting

3.1. Fabric Structures in Circular Knitting

This semester focuses on the intricate world of fabric structures in circular knitting. Students will learn how to create different textures, patterns, and designs by manipulating the machine settings.

3.2. Pattern Knitting Techniques

Students will explore pattern knitting techniques, allowing them to create unique and customized designs on knitted fabrics. This skill is essential for producing a variety of textiles.

Semester 3: Quality Control and Troubleshooting

4.1. Quality Control in Circular Knitting

Ensuring the quality of knitted fabrics is a critical aspect of the circular knitting operator's role. This semester will cover techniques for quality control and inspection.

4.2. Troubleshooting Common Issues

Students will also learn how to identify and rectify common issues that may arise during the knitting process. Troubleshooting skills are invaluable in maintaining a smooth production flow.

Semester 4: Advanced Circular Knitting

Advanced Stitch Techniques

This semester introduces advanced stitch techniques, enabling students to produce intricate and specialized fabric designs. These skills can be used to create high-value textiles.

Circular Knitting for Specialized Fabrics

Students will explore circular knitting applications for specialized fabrics, such as sportswear, medical textiles, and more. Understanding the unique requirements of these sectors is crucial for a successful career.

Semester 5: Finishing and Production

6.1. Fabric Finishing

After knitting, fabrics often require finishing processes for enhanced properties. This semester covers techniques for fabric finishing, including washing, dyeing, and printing.

6.2. Production Planning and Optimization

Students will learn about production planning and optimization, ensuring that production targets are met efficiently and cost-effectively.

Semester 6: Internship and Practical Experience

7.1. Real-World Application

In the final semester, students will put their knowledge into practice through an internship. This real-world experience is invaluable for gaining industry insights and building a professional network.

7.2. Internship and Project Completion

During the internship, students will complete a project relevant to circular knitting. This project showcases their skills and creativity.

Career Opportunities

After completing the syllabus, graduates can explore various career opportunities as circular knitting machine operators. These positions can be found in textile manufacturing companies, fashion industry, and textile research organizations.

Internship opportunities after completing KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

After successfully completing the course on "KNITTING MACHINE OPERATOR – CIRCULAR KNITTING," graduates will find themselves well-prepared to embark on a rewarding career in the textile industry. One of the pivotal aspects of this training program is the opportunity for internships, and it's important to understand the numerous benefits associated with internships in this field.

Practical Application: Internships offer the chance to apply the knowledge and skills learned during the course in a real-world setting. It's one thing to understand the theory behind circular knitting, but hands-on experience is invaluable. Interns get to work directly with circular knitting machines, yarns, and fabric production, gaining practical insights.

Skill Refinement: Internships provide a platform for refining and honing the skills acquired during the training. This includes machine operation, troubleshooting, quality control, and fabric finishing. Supervisors at the internship sites often guide and mentor interns, helping them become more proficient in their roles.

Industry Connections: Internships offer the opportunity to build connections within the textile and fashion industry. These connections can be crucial for finding job opportunities after completing the internship. Networking with industry professionals, supervisors, and colleagues can lead to job recommendations and references.

Resume Enhancement: Having an internship on your resume is a significant advantage when applying for full-time positions as a circular knitting machine operator. It demonstrates practical experience and a commitment to the field, making you a more attractive candidate to potential employers.

Exposure to Specialized Areas: Depending on the type of internship and the host organization, interns may have the chance to work with specialized fabrics or in unique sectors like sportswear, medical textiles, or high-end fashion. This broadens their skill set and opens doors to various career paths.

Career Pathway: Internships often serve as stepping stones to permanent positions. Many organizations hire interns who have demonstrated dedication and competence during their internship. Graduates of the training program may find themselves transitioning directly into paid roles in the same companies.

Learning Environment: Interns are exposed to different approaches, techniques, and equipment used in the industry. This diverse learning environment fosters adaptability and the ability to work in various settings.

Industry Awareness: Through internships, participants gain a deeper understanding of the challenges and opportunities within the circular knitting industry. They become aware of market trends, consumer demands, and emerging technologies, which can be advantageous in their future careers.

Scholarships and grants for KNITTING MACHINE OPERATOR – CIRCULAR KNITTING

Scholarships and grants for individuals pursuing a career as a "KNITTING MACHINE OPERATOR – CIRCULAR KNITTING" can significantly ease the financial burden of education and training. These financial assistance options are especially important for students and aspiring professionals who are passionate about circular knitting but may have limited resources. Here are some potential sources of scholarships and grants in this field:

Educational Institutions: Many technical and vocational schools, as well as community colleges, offer scholarships or grants to students enrolled in programs related to textile and knitting technology. These awards can cover tuition, fees, and even living expenses.

Industry Associations: Various textile and knitting industry associations may provide scholarships or grants to students pursuing careers in circular knitting. Examples include the National Council of Textile Organizations (NCTO) and the American Association of Textile Chemists and Colorists (AATCC).

Private Foundations: Some private foundations and organizations have a mission to support education in the textile industry. They may offer scholarships to students pursuing degrees or certifications in knitting machine operation or related fields.

Employer-Sponsored Programs: Some companies in the textile and fashion industry offer educational support to their employees. If you are already working in a related field, inquire if your employer has a program in place to help fund your education and training.

State and Federal Aid: In many countries, there are government-funded financial aid programs, including grants and loans, for students pursuing post-secondary education and vocational training. The availability of such programs varies by region.

Textile and Fashion Schools: Some specialized institutions that focus on textiles and fashion may offer their own scholarships or grants to attract talented students. These awards are often based on academic achievement, skills, or other criteria.

Online Scholarship Databases: Several online scholarship databases list a wide range of scholarships available to students pursuing vocational and technical training. Websites like Fastweb and Scholarships.com can help you search for relevant opportunities.

Local and Community Organizations: Community organizations, rotary clubs, and local businesses may offer scholarships to students residing in their communities. These scholarships may not be large, but they can be helpful in covering educational expenses.

When seeking scholarships and grants for a "KNITTING MACHINE OPERATOR – CIRCULAR KNITTING" program, consider the following tips:

Research thoroughly to identify all potential sources of financial aid.

Pay attention to eligibility criteria, application deadlines, and required documents.

Prepare a strong application, including a well-written essay or personal statement highlighting your passion for circular knitting.

Seek advice from your school's financial aid office for additional assistance.

CONCLUSION

In conclusion, the role of a knitting machine operator in circular knitting is a vital one. These professionals play a significant part in the textile industry, ensuring the efficient production of high-quality seamless fabrics. As the industry continues to evolve, so do the opportunities for skilled operators.

FAQ,s

What does a Knitting Machine Operator - Circular Knitting do?

A Knitting Machine Operator in circular knitting is responsible for operating knitting machines to produce fabrics in a continuous, circular fashion. They set up machines, select yarn, and ensure the quality of the knitted fabric.

What are the key skills required for this role?

Essential skills include proficiency in operating circular knitting machines, understanding fabric structures, troubleshooting machine issues, quality control, and knowledge of yarn selection and preparation.

How can I become a Knitting Machine Operator - Circular Knitting?

You can become a Knitting Machine Operator by enrolling in a training program or course specifically focused on circular knitting. Once you complete the program, you can seek internships and entry-level positions in textile manufacturing.

Are there specific types of circular knitting machines that I need to be trained on?

Circular knitting operators may work with various types of machines, such as single jersey machines, rib knitting machines, and interlock machines. Training programs typically cover multiple machine types to prepare you for different roles.

Is it a physically demanding job?

While it may involve standing for long periods and repetitive tasks, circular knitting machine operation is not excessively physically demanding. It primarily requires attention to detail and precision.

What kind of industries employ Knitting Machine Operators in circular knitting?

Knitting Machine Operators are employed in various industries, including textile manufacturing, fashion, sportswear, and medical textiles.

Is there room for career advancement in this field?

Yes, there are opportunities for career advancement. Experienced Knitting Machine Operators can move into supervisory roles, quality control, or become specialists in pattern knitting and fabric development.

Are there any safety concerns in this role?

Circular knitting machine operators should be aware of safety precautions, as there can be risks associated with machine operation. Training programs often include safety training to minimize these risks.

What is the average salary for Knitting Machine Operators in circular knitting?

Salaries can vary depending on location, experience, and the specific industry. On average, Knitting Machine Operators earn a competitive salary within the textile industry.

Where can I find training programs for circular knitting machine operation?

Training programs can be found at technical and vocational schools, community colleges, and online institutions. You can also inquire about programs through industry associations and local textile manufacturers.